For industrial butchers, the answer to whether to cut meat in house is an easy one: Of course! How else would it get done?

But for commercial foodservice providers and retail operations like supermarkets, the choice to invest in meat cutting technology involves more than double checking the price tag. Cutting meat on site could change the entire dynamic of your business – for better or for worse. So, before you purchase an industrial meat saw, take time to consider these vital questions:

1. Will cutting meat really be cost-effective?

Chances are, buying primal or subprimal cuts of beef wholesale and dicing them up yourself will be less expensive than purchasing retail cuts from the start. The additional processing will no doubt come at a cost to the buyer.

However, obviously these costs won’t disappear if your business decides to purchase less processed meat and cut it on site. Will labor and employee training costs, as well as machinery upkeep, rival or exceed the savings retained through primal and subprimal meat procurement?

“Purchasing the right equipment from the right distributor could swing cost savings in your favor.”

That’s up to the decision-makers to determine. That said, purchasing the right equipment from the right distributor could swing cost savings in your favor. For instance, all Horizon Bradco equipment purchases include employee training sessions and ancillary video resources. Additionally, you have the option of purchasing a preventative maintenance plan through Horizon Bradco. With these costs cutting features, perhaps cutting your own meat may be a more realistic endeavor.

2. Do you have the storage space?

Depending on how retailers plan on processing their product, the bigger the cut of meat at the point of procurement, the greater the necessity for more spacious backend refrigeration. Primal and subprimal cuts cannot be as easily and efficiently shelved as retail-ready packages. Businesses must be flexible enough to adjust meat delivery times to correspond with a regimented cutting schedule. That way, butchers can saw the meat immediately as it arrives, vacuum seal it for future use and freeze cuts sensibly, utilizing every square inch of cold storage available

That said, taking on larger cuts and perhaps a greater volume of byproduct – more on that in a bit – retailers may also need to invest in larger refrigerated cases to accommodate, not to mention make room in the budget for the possibility of higher energy costs.

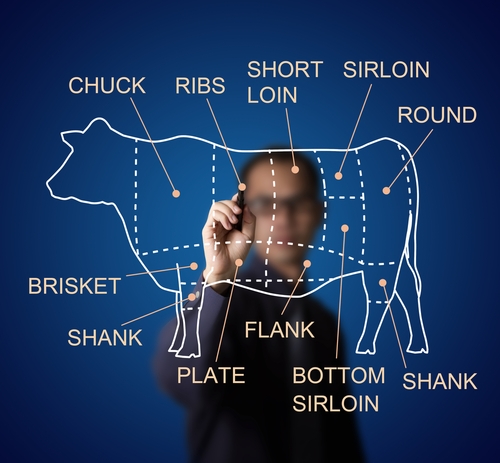

3. Do you have the creativity to capitalize on less popular cuts?

On-site meat cutting allows butcher block staff to experiment with cuts of meat perhaps previously underutilized. First, retailers that expand their meat selections to include less expensive products like beef chuck, hanger steak or pork shoulder entice shoppers to spend when they might otherwise balk at higher per pound pricing elsewhere.

Second, featuring less popular cuts in prepared foods specials both highlights their versatility and provides businesses the opportunity to sell these goods at a markup, then refer customers to retail-ready packages to try their own hand at a similarly delicious meal. Is your staff up for the challenge?